Ultraviolet Sterilization Technology The Science Behind the Product

A water treatment system

A water treatment systemHow Can "Light" Kill Bacteria?

Ultraviolet disinfection systems are mysterious to many people - how can "light" kill bacteria? But the truth is it can. Ultraviolet (UV) technology has been around for more than 60 years, and its effectiveness has been well documented both scientifically and commercially. It is nature's own disinfection/purification method. With consumers becoming more concerned about chlorine and other chemical contamination of drinking water, more dealers are prescribing the ultraviolet solution suitable for both small flow residential applications as well as large flow commercial projects.

Ultraviolet is a means of killing or rendering harmless microorganisms in a dedicated environment. These microorganisms can range from bacteria and viruses to algae and protozoa. UV disinfection is used in air and water purification, sewage treatment, protection of food and beverages, and many other disinfection and sterilization applications. A major advantage of UV treatment is that it is considered safer and more reliable for disinfection of water than chemical alternatives, while the level of disinfection is much higher. UV treatment systems are also extremely cost efficient and require less space than alternative disinfection systems.

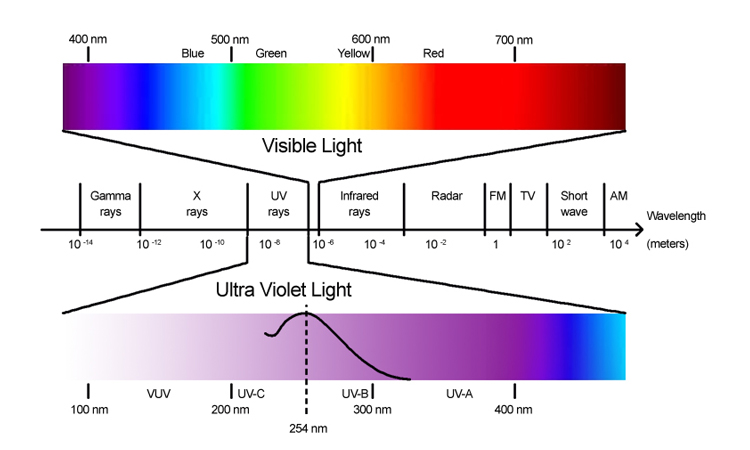

The Electromagnetic Spectrum

The Electromagnetic SpectrumWhat is UV and How Does it Work?

Ultraviolet light is one energy region of the electromagnetic spectrum, which lies between the x-ray region and the visible region. Wavelenghts of visible light range between 400 and 700 nanometers (nm). UV itself lies in the ranges of 200 nm to 390 nm. Optimal UV germicidal action occurs at 254 nm.

Since natural germicidal UV light from the sun is screened out by the earth's atmosphere, we must look to alternative means of producing UV light. This is accomplished through the conversion of electrical energy in a low-pressure mercury vapor "hard glass" quartz lamp. Electrons flow through the ionized mercury vapor between the electrodes of the lamp, which then creates UV light.

The Filaments and Arc in a UV lamp

The Filaments and Arc in a UV lampUltraviolet light is one energy region of the electromagnetic spectrum, which lies between the x-ray region and the visible region. Wavelenghts of visible light range between 400 and 700 nanometers (nm). UV itself lies in the ranges of 200 nm to 390 nm. Optimal UV germicidal action occurs at 254 nm.

As UV light penetrates through the cell wall and cytoplasmic membrane of a microorganism that is in the water while it flows through the unit, it causes a molecular rearrangement of the microorganism's DNA, which prevents it from reproducing. If the cell cannot reproduce, it is considered dead or "inactivated".

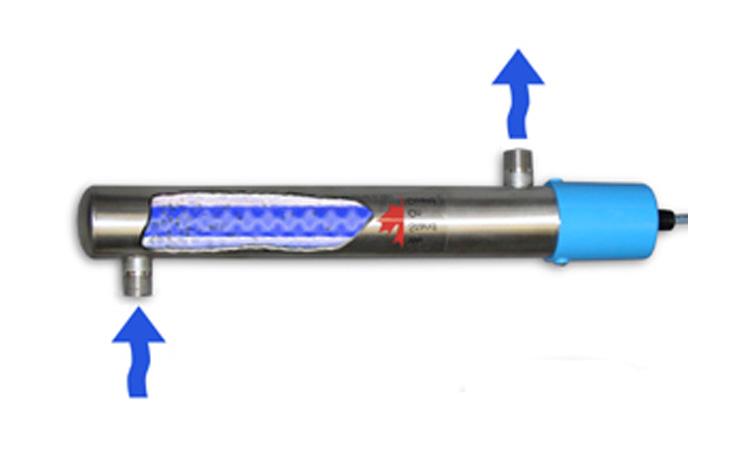

Water flows through the chamber in a circular path

Water flows through the chamber in a circular pathDosage

UV dosage is the most critical function of UV disinfection, because the extent of inactivation is proportional to the dose applied to the water. As individual UV lamps emit a set amount of ultraviolet energy, it is important that a system be sized correctly. Flow rates are the determining factor and must not be overstated. Contact time, which is the time the water is within the sterilization chamber, is directly proportional to dosage, which is the amount of energy per unit area (calculated by dividing the output in watts by the surface area of the lamp), and thus the overall effectiveness of microbial destruction in the system. This product of intensity and time is known as the Dose and is expressed in microwatt seconds per centimeter squared (μWsec/cm2). Divide by 1000 to express the dose in the preferred notation mJ/cm2 (milli joule per centimeter squared).

DOSE = time (sec) x output (watts) over area (cm2)

For maximum UV transmission a "hard glass" quartz sleeve is recommended for two main reasons. It isolates the lamp from the water to offer more uniform operating temperatures and allows for higher UV output into the water.

Monitor and Solenoid Valve for Fail-safe Operation

Monitor and Solenoid Valve for Fail-safe OperationOptional Features

A variety of optional features may be added on to the UV sterilizers. They include UV monitoring devices that measure the actual UV output in real time, solenoid shut-off devices that will stop the water flow in the event of a system failure, flow control devices to properly limit the water flow in the units, audible and visual alarms (both local and remote) to warn of lamp failures, high temperature sensors to monitor excessive temperatures in the reactor chamber or control panel, and hour meters to monitor the running time of the UV lamps.

A typical residential UV water treatment system

A typical residential UV water treatment systemAdvantages of UV Sterilization

Here are some of the advantages of using UV and microfiltration over other water treatment technologies:

- Environmentally friendly, no dangerous or toxic chemicals to handle, no problem of overdosing (it's impossible), no need for specialized storage equipment, no WHMIS requirements.

- Low initial capital cost as well as reduced operating expenses when compared with similar technologies such as ozone, chlorine, etc.

- Immediate treatment process, no need for holding tanks, long retention times, etc.

- Extremely economical, hundreds of gallons may be treated for each penny of operating cost.

- No chemicals are added to the water supply - no chlorinated by-products are generated (i.e. chlorine + organics = trihalomethanes).

- No change in taste, odor, pH or conductivity or the general chemistry of the water, essential minerals and trace elements remain in the water.

- Automatic operation without special attention or measurement, operator friendly.

- Simplicity and ease of maintenance, periodic cleaning (if applicable) and annual lamp replacement, no moving parts to wear out.

- Easy installation, only two water connections and a power connection.

- Compatible with all other water processes (i.e. RO, ultrafiltration, ion exchange, etc.)

Water is Life

Water is LifeFactors Affecting UV

Because UV does not leave any measurable residual in the water, it is recommended that the UV sterilizer be installed as the final step of treatment and located as close as possible to the final distribution system. Once the quality of your water source has been determined, you will need to look at things that can inhibit the UV from functioning properly (e.g., iron, manganese, TDS, turbidity, and suspended solids).

Iron and Manganese will cause staining on the quartz sleeve and prevent the UV light from transmitting into the water at levels as low as 0.3 ppm of iron and 0.05 ppm of manganese. Proper pretreatment is required to eliminate this staining problem.

Total Dissolved Solids (TDS) should not exceed 500 ppm. There are many factors that make up this equation such as the particular make-up of the dissolved solids and how fast they absorb on the sleeve, again impeding the UV energy from penetrating the water.

Turbidity is the inability of light to travel through water. Turbidity makes water cloudy and aesthetically unpleasant. In the case of UV, levels over 1 NTU can shield microorganisms from UV light, making the process ineffective.

Suspended Solids need to be reduced to a maximum of 5 microns in size. Larger solids have the potential of harboring or encompassing the micro-organisms and preventing the necessary UV exposure. Pre-filtration is a must on all UV applications to effectively destroy microorganisms to a 99.9 % kill rate.

Additional Factors - UV levels fluctuate with temperature levels. The optimal operating temperature of a UV lamp must be below or near 40 °C (104 °F). Typically, a quartz sleeve is installed to buffer direct lamp-water contact, thereby reducing any temperature fluctuations. The UV dose applied to the water decreases significantly with temperatures over 40 °C.

Water Treatment System at a Juicemaker's Plant

Water Treatment System at a Juicemaker's PlantUV Applications

One of the most common uses of ultraviolet sterilization is the disinfection of domestic water supplies due to contaminated wells or surface water sources. Coupled with appropriate pre-treatment equipment, UV provides an economical, efficient and user-friendly means of producing safe potable water.

The following list shows where ultraviolet technology is currently in use:

Integrated Water Treatment System

Integrated Water Treatment SystemInstallation and Maintenance Guidelines

Once the application has been determined, you should find a location that offers easy access for service. You will need to have access to the pre-filters, to the UV chamber for annual lamp changes and regular maintenance on the quartz sleeve. You will want to locate near an electrical outlet. Note: Using a UV system and a pump on the same electrical line may cause problems and shorten the life of the UV lamp and ballast. A surge protector with a rating of at least 3600 Joules should be installed to protect the electronic ballast from damage due to power spikes or lightning strikes. UV units are installed on the cold water line before any branch lines and should be the last point of treatment. Clearance for lamp change has to be considered during installation. All points of the distribution system after the sterilizer must be chemically "shocked" to ensure that the system is free from any downstream microbial contamination. Lamp changes should be done at least once every year. Filter changes are done according to the condition of the feed water. If there is residue left, you may need to use a non-abrasive cleaner that does not scratch the surface and is formulated to remove iron and scale buildup. Do not leave fingerprints on the glass! It is imperative to follow the manufacturers guidelines on feed water quality and operational procedures.

Summary

The need for ultraviolet sterilization products can be found in virtually all areas in both residential and commercial applications alike. Its simplistic design, ease of maintenance and low capital and operating costs make UV disinfection the number one choice in contaminated water situations. Because of its advantages, UV irradiation is on the way to become the most popular choice for the disinfection of water supplies in the 21st century.

Next time, purify water "natures way" . . . use ultraviolet light.